Alber BDS-256XL Battery Monitoring and Diagnostic System

Alpine Power Systems' experienced technical support & sales team is here to assist your needs:

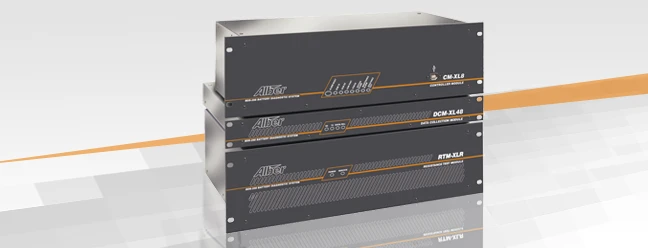

The Alber BDS-256XL is a modular system that can monitor virtually any UPS battery configuration. The BDS-256XL consists of a Controller, Data Collection Module, and Resistance Test Module.

On this page:

Battery diagnostic systems (BDS) continuously monitor all critical battery parameters, verify the integrity of the connected battery system, and alarm on any out-of-tolerance condition. Testing includes proactive, internal DC cell resistance measurements at programmed intervals recommended by IEEE standards. By tracking increases in internal cell resistance, the BDS predicts if the battery system will perform during a power outage.

The BDS-256XL is a modular system that can monitor virtually any UPS battery configuration. The BDS-256XL consists of a Controller, Data Collection Module, and Resistance Test Module.

Interface to the BDS-256XL is done using the Alber Battery Monitor Data Manager (BMDM) software. The Battery Monitor Report Generator program creates reports from collected data.

The CM-XL8 Controller

The Controller, the brain of the system, coordinates alarms and traffic to and from the other system components. It can monitor up to eight strings of 256 cells on independent UPS's, for a total of 2048 cells per Controller. Its nonvolatile memory can hold up to a year's worth of data. The built-in power supply provides 24VAC for all components in the system.

The DCM-XL48 Data Collection Module

The Data Collection Module (DCM) is a scanning voltmeter that acquires overall voltage, cell voltage, current, and temperature readings from the monitored battery string. The DCM can monitor cells or blocks from 1V to 16VDC. The DCM compares captured data with preset thresholds and alerts the user if any parameters are in violation. Each DCM can measure up to 48 cells or battery blocks per string. DCM's can be connected in series to monitor up to 256 cells per string. The DCM also controls the load module during a resistance test.

The RTM-XLR Resistance Test Module

The Resistance Test Module (RTM) provides the load during the patented resistance test. Without this component, the monitor system could not provide the high reliability and repeatable results that Alber customers rely on.

Real Time Data Capture

● Overall String Voltage

● Individual Cell Voltage

● Ambient Temperature

● Discharge Current

● Float Current

● Discharge Event

Proactive Continuity and Integrity Testing

● User programmable DC resistance tests

● Internal cell resistance test (Battery State of Health)

● Intercell and Intertier connection resistance test

Battery Management

● Vital battery parameters are continuously compared to user programmable alarm thresholds

● Detailed analysis and report generation with the BMDM - Battery Monitor Data Manager software

● No onsite computer is required for data collection and alarming - multiple remote communication

options

● Easily integrates to building management systems

Alpine Power Systems is a value-added reseller of Alber products. Alpine can provide battery testing equipment services on all Alber products including engineering, installation, preventative maintenance, monitoring and recycling. Alpine provides services for data centers, telecom, healthcare, oil & gas and many other applications. Call our inside sales group at 877-993-8855 for assistance.

Manufacturer

See below for documentation relating to this product line that is available to download. To download this documentation, please click on the desired document you’d like to download and fill out the required form information fields. You will be able to view and download the documents upon completion of the download form.

Find Alber BDS-256XL Battery Monitoring and Diagnostic System in the following product categories:

Manufacturer